Digital forms in the cosmetics industry are presented as great allies for the daily management of manufacturing controls of these products, with a great demand in the market.

In a highly regulated and technically demanding industry, digital forms make it possible to record critical production data, ensure batch traceability and facilitate compliance with current regulations.

In this way, the use of smart forms directly impacts the quality of the final product, operational efficiency and responsiveness to audits and inspections.

The weight of the cosmetics industry in Spain

Cosmetic manufacturing requires precise documentation of each stage of the production process: from the receipt of raw materials to the final controls before batch release.

Thus, the digitization of these records, through structured and controlled forms, responds to a real need of the cosmetics industry.

According to Stanpa (National Association of Perfumery and Cosmetics), the cosmetics and perfume industry reached a consumption of more than 11.2 billion euros in 2024, with a growth of 7.7% compared to 2023, and a representation of 1.03% of the national GDP.

It also states that the sector exported products worth 9,589 million euros, consolidating its position as one of the country’s main industrial engines and an international benchmark in manufacturing and exports.

This volume of activity implies a high level of production complexity and great responsibility in terms of safety, quality and regulatory compliance, factors that make rigorous management of the information generated in the plant essential.

Regulatory framework applicable to cosmetic manufacturing in Spain

The manufacture of cosmetics in Spain is mainly regulated by Regulation (EC) No. 1223/2009 on cosmetic products, which is directly applicable in all European Union Member States.

This regulation establishes the obligation to ensure that cosmetic products are safe for human health and requires full technical documentation associated with each product.

Among other obligations, the manufacturer must keep detailed information on:

- Qualitative and quantitative formula

- Manufacturing methods

- Safety evaluation

- Batch data produced

Good Manufacturing Practices (ISO 22716)

The European regulation establishes that cosmetic products must be manufactured in accordance with Good Manufacturing Practices (GMP), as set out in the ISO 22716 standard. This standard requires documented records of processes, controls and responsibilities, making orderly and reliable management of manufacturing data essential.

In this context, digital forms become the natural support to meet these documentary requirements.

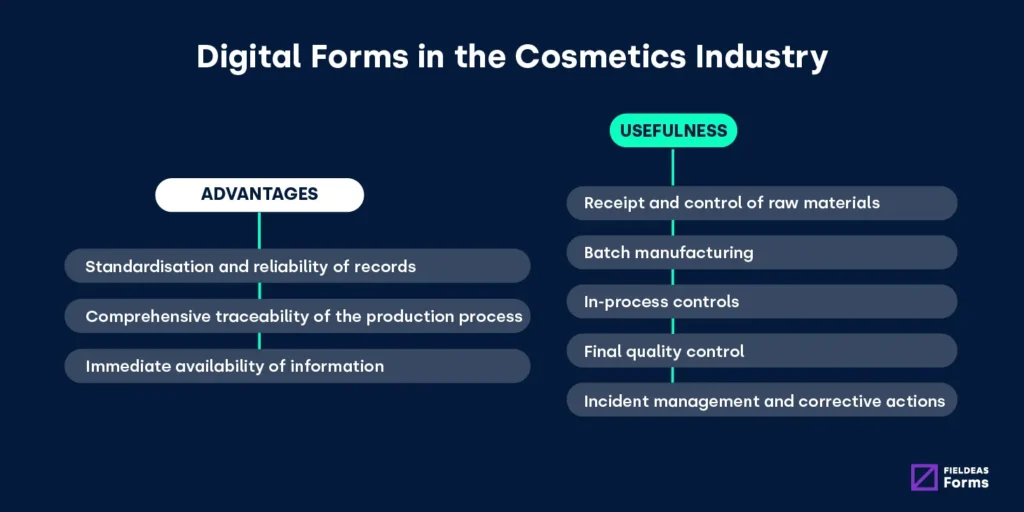

How digital forms help in cosmetics manufacturing

Standardization and reliability of records

Digital forms allow defining mandatory fields, drop-down lists and automatic validations. This ensures that all operators record information in the same way, reducing variations and errors derived from manual paper records.

Each form is associated with a user, a date and a specific batch, generating a complete and verifiable traceability.

Complete traceability of the production process

In cosmetics manufacturing, traceability is not optional. Digital forms make it possible to follow the complete path of a batch, from raw material to finished product, facilitating the investigation of incidents and the management of recalls if necessary.

Immediate availability of information

Digital records allow real-time access to information from any authorized point in the plant. This is key for production, quality or audit managers, who can review data without relying on physical files.

Concrete examples of the use of digital forms in the cosmetics industry

Reception and control of raw materials

When a warehouse operator receives a raw material, he accesses the digital receiving form from a tablet or terminal. In it he enters:

- The raw material code

- The supplier’s lot number

- The amount received

- The date of receipt

Then attach the certificate of analysis provided by the supplier and mark the status of the material as “pending control”.

The quality manager then reviews the form, validates the data and changes the status to “approved” or “rejected”. Only approved batches are available in the system for use in manufacturing.

Batch production forms

During production, the responsible operator opens the digital form for the assigned batch. The form guides him step by step through the process:

- Enter the actual weight of each ingredient.

- Records temperature and mixing time

- Confirm each step before proceeding to the next one.

If a value is outside the defined ranges, the system requests a justification before continuing. At the end, the form is closed and digitally signed, being linked to the manufactured batch number.

Controls in process

At certain points in the process, the quality operator takes intermediate samples. He uses a specific digital form where he records:

- Sampling time

- Measured parameters (pH, viscosity, appearance)

- Compliant or non-compliant result

If any parameter does not meet the specifications, the form automatically generates an alert for the production manager, who can either stop the process or apply a documented correction.

Final quality control

Before releasing the batch, the laboratory technician accesses the final digital control form. He enters the results of the physicochemical and microbiological tests and attaches the corresponding analytical reports.

The quality manager reviews the form, verifies that all criteria are met and authorizes the batch release by digital signature. This record is filed as part of the product file.

Incident and corrective action management

If a deviation is detected during manufacturing, the operator records the issue on a digital nonconformance form. He describes the problem, the time at which it was detected and the batch affected.

Subsequently, the assigned manager documents on the same form the root cause analysis and the corrective and preventive actions (CAPA). The system allows tracking of these actions until they are closed, maintaining a complete history for audits.

FIELDEAS Forms in quality control in the cosmetics industry

The use of digital forms in the cosmetics industry through solutions such as FIELDEAS Forms provides concrete advantages over paper records in manufacturing environments:

- Reduction of transcription errors, by recording data directly in structured digital forms with automatic validations.

- Elimination of documentation losses, thanks to centralized and secure storage of all manufacturing and quality records.

- Streamlined audits and inspections, with forms organized by batch, process and date, immediately accessible.

- Facilitation of historical data analysis, allowing the recorded information to be exploited for continuous improvement of production processes.

- More robust compliance with Good Manufacturing Practices (GMP – ISO 22716), ensuring complete, traceable and auditable records.

- Significant reduction in the use of paper, in line with the sustainability objectives of the cosmetics sector.

Thus, FIELDEAS Forms allows cosmetics manufacturers to transform the forms required by Good Manufacturing Practices into reliable digital processes, auditable and aligned with the actual plant operations , thus facilitating a more efficient management of production and strengthening the competitiveness of the cosmetics industry.