In an industrial environment increasingly focused on efficiency, safety and traceability, digital forms in industry have become a key tool for digitizing processes, connecting teams and making better decisions. We are no longer just talking about replacing paper: we are talking about transforming how information is collected on the shop floor, how it is shared and how it is analyzed in real time.

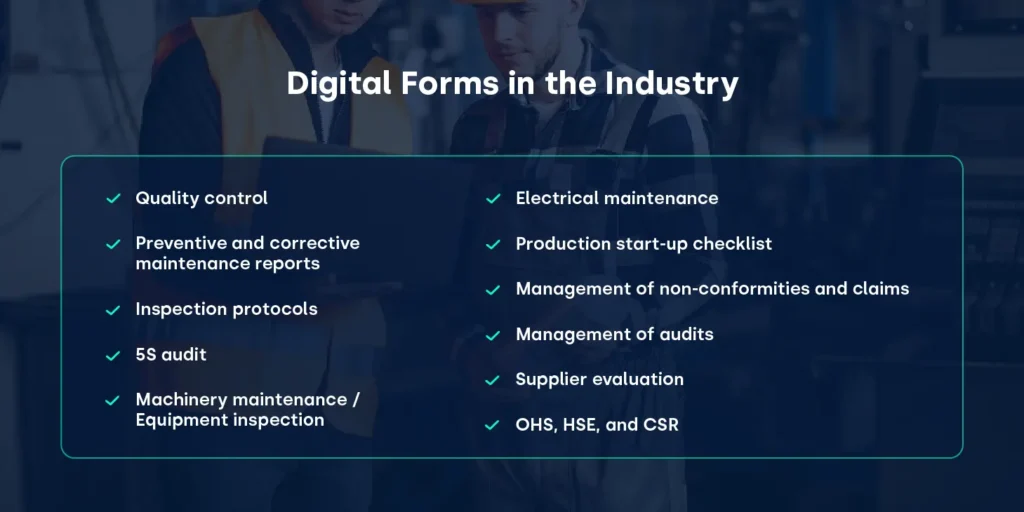

From quality control to machinery maintenance, from supplier evaluation to ORP management, the use cases are as varied as they are powerful. In this post we explore the main benefits and the specific scenarios where digital forms make a difference.

Why use digital forms in the industry?

Adopting digital forms is not only a question of modernization, but also of operational profitability.

Replacing paper forms with digital solutions allows data to be captured directly from the field, automatically validated, shared instantly and integrated with management systems.

Key benefits of digital forms in the industry

- Structured, real-time data collection from any device.

- Elimination of errors due to manual retyping or loss of documents.

- Advanced electronic signature to validate actions with legal validity.

- Direct connection between field operators and technical offices.

- Automatic activation of workflows or alerts based on collected data.

- Immediate report generation, with full traceability.

- Improved regulatory compliance, safety and sustainability.

Use cases of digital forms for the industry

Below, we review the main processes where digital forms for industry are already generating real value.

Quality control

Digital forms allow for standardized quality inspections, capturing accurate data, photographs, observations and signatures in real time.

In addition, they also facilitate the detection of non-conformities, the follow-up of corrective actions and the generation of automatic reports for root cause analysis and continuous improvement.

Preventive and corrective maintenance reports

The online forms make it possible to completely digitize the management of industrial maintenance.

In other words, technicians can record each intervention (preventive or corrective), add observations, attach images, digitally sign and schedule new revisions.

On the other hand, historical records are also generated to help analyze failures and improve asset availability.

Inspection protocols

Inspection processes are standardized by means of digital forms adapted to each equipment, product or area.

This ensures regulatory compliance, facilitates audits and enables agile decision making based on homogeneously and accurately collected data.

5S Audit

Implementing 5S audits digitally allows to evaluate compliance with the principles of classification, order, cleanliness, standardization and discipline.

The digital forms facilitate the identification of critical points, the follow-up of corrective actions and the promotion of a culture of continuous improvement in the plant.

Machinery maintenance and equipment inspection

Digital forms allow complete control over the status of each piece of equipment or production line.

Thus, you can record each revision, view the history, schedule maintenance and detect possible failures before they affect operations. All from a single environment, accessible from the field or the back office.

Electrical maintenance

Electrical maintenance management on industrial platforms also benefits from digitalization.

With digital forms, detailed reports on inspections, safety tests, performances and repairs can be generated.

In addition, these forms assist in planning, prevent electrical hazards and improve the traceability of installations.

Production start-up checklist

Intelligent digital forms make it possible to ensure that everything is in order before starting production, vital to avoid errors and delays.

These tools allow you to verify each step in a guided manner, record incidents and ensure that the line starts up in optimal conditions. They also allow you to analyze historical data to detect areas for improvement.

Management of non-conformities and complaints

With digital forms, nonconformities can be recorded from the field immediately, with photographs, observations and automatic classifications.

It is also possible to activate action plans, assign responsible parties and follow up on their resolution, all with full traceability.

Audit management

Both internal and external audits can be organized and executed using digital forms that collect results, evidence, scores and observations.

This reduces preparation time, improves the quality of the data collected and facilitates subsequent analysis.

Supplier evaluation

The periodic evaluation of suppliers can be systematized with forms adapted to the criteria of each company.

This facilitates objective comparison, traceability of decisions and detection of critical suppliers based on real data.

PRL, HSE and CSR

The management of occupational risk prevention (ORP), health, safety and environment (HSE), and corporate social responsibility (CSR) can also be digitized.

The forms allow you to record incidents, safety inspections, PPE audits, environmental assessments and more. This not only reduces risks, but also helps to comply with international regulations and standards.

How to implement digital forms in the industry?

Implementing digital forms in industrial environments is easier than it sounds. The process can start in key areas where paper still creates inefficiencies.

- Identifies critical or repetitive processes with high volume of documentation.

- It designs specific and guided forms, adapted to each type of operation.

- Train operators to ensure easy and efficient adoption.

- Integrate forms with existing systems (ERP, CMMS, BI).

- Periodically analyzes the data collected to optimize processes and decisions.

FIELDEAS Forms for industrial environments

Digital forms for industry are a real lever for transformation. They make it possible to reduce errors, gain traceability, speed up decision-making and, above all, effectively connect field work with operational management.

In a context where every failure costs time and money, and where competitiveness increasingly depends on the ability to act with real-time data, digitizing forms is not an option, it is a valuable strategy.

The sooner the step is taken, the sooner the results in efficiency, quality, compliance and sustainability will be seen.

In this sense, FIELDEAS Forms is presented as a comprehensive, accessible and highly efficient solution to digitize operational processes in industrial environments, facilitating data collection in the field, improving traceability and optimizing decision making in real time.

Discover some real-life success stories of how digital forms are being used in businesses.