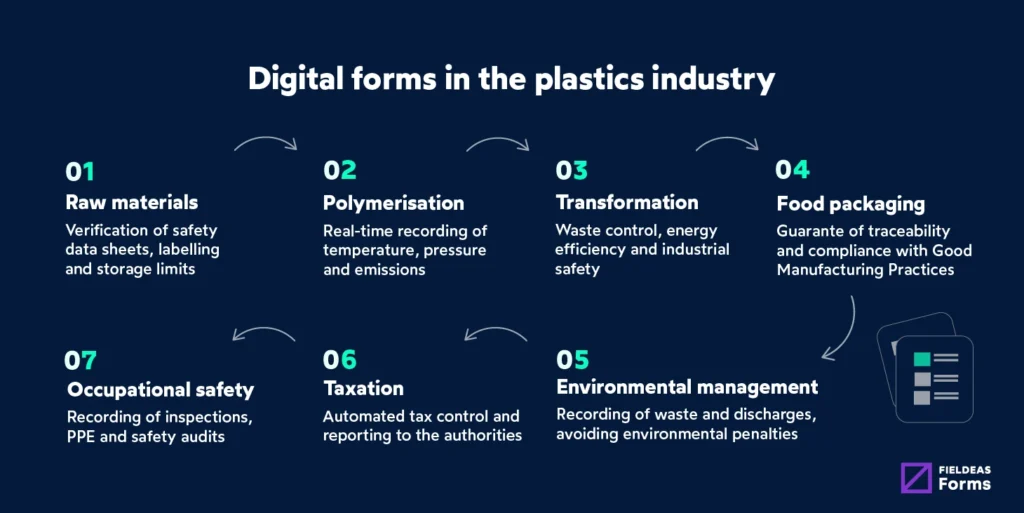

Digital forms in the plastics industry have become an essential tool to ensure regulatory compliance, improve efficiency and reduce risks at all stages of plastics manufacturing.

- Digital forms in the reception and storage of raw materials

- Smart forms in the polymerization or resin synthesis stage

- Online forms at the processing stage: extrusion, injection or blow molding

- Digital forms in the manufacturing stage of food contact packaging or materials

- Intelligent forms in the environmental and waste management phase

- Digital forms in the marketing phase and taxation of plastics

- Online forms in industrial and occupational safety and security

- Digital forms software in the plastics industry

The plastics industry is undergoing a profound transformation. Regulatory pressure, environmental taxes, the transition to the circular economy and increasing traceability requirements have made document management and process control a real challenge for manufacturing companies.

Below, we take a step-by-step look at how a digital forms digital forms solution can help plastics producers comply with Spanish and European regulations, and maintain comprehensive control at every stage of the process.

Digital forms in the reception and storage of raw materials

In this first phase, companies receive and store the raw materials needed to manufacture plastic products, such as monomers, additives, pigments and solvents.

This point is strongly regulated by regulations such as the REACH Regulation concerning the Registration, Evaluation, Authorization and Restriction of Chemicals (EC 1907/2006); the CLP Regulation (EC 1272/2008), on classification, labeling and packaging of substances and mixtures; Royal Decree 840/2015 (Seveso III) on major accident prevention; and the Chemical Storage Regulation (APQ).

The digital forms allow the automatic registration of the receipt of raw materials, verifying that each substance has its corresponding Material Safety Data Sheet (MSDS) and is correctly labeled according to the CLP (Classification, Labelling and Packaging) regulation.

In addition, the forms can incorporate automatic chemical storage inspection (APQ) checklists, verify compliance with storage limits and issue alerts if risk thresholds are exceeded or permits expire.

Benefits of digital forms

With the above, we can state that the main benefit of digital forms, such as FIELDEAS Forms, in the phase of reception and storage of raw materials for the manufacture of plastics is to ensure the traceability of raw materials and avoid penalties for non-compliance with REACH or APQ regulations through verified digital records.

Smart forms in the polymerization or resin synthesis stage

The second phase of the process consists of the chemical reaction to obtain polymers such as PE (polyethylene), PP (polypropylene) and PVC (polyvinyl chloride).

Here the most relevant regulations are Law 34/2007 on air quality, Royal Decree 815/2013 on industrial emissions, Law 21/2013 on environmental assessment and Seveso III.

Critical variables (temperature, pressure, emissions) are monitored during polymerization. Here, digital forms in the plastics industry make it possible to create automatic records of these parameters in real time and store the information in the cloud.

This data is vital to comply with the requirements of the Integrated Environmental Authorization (AAI) and the Best Available Techniques (BAT/BAT) required by the administration.

In addition, the digital forms allow programming alerts if emission limits are exceeded, generating automatic reports for environmental authorities and keeping a digital log of preventive maintenance, reducing risks and avoiding penalties.

Benefits of smart forms

Thus, the main benefit of FIELDEAS Forms smart forms in the polymerization or resin synthesis phase is to obtain traceability and continuous control of emissions and processes to comply with environmental and industrial regulations.

Online forms at the processing stage: extrusion, injection or blow molding

At this stage, the plastic is transformed into products by heat and pressure. It is one of the most energy-intensive stages and generates waste and emissions.

At this point, the key regulations are Law 7/2022, on waste and contaminated soils for a circular economy; Law 34/2007 on air quality; and the obligations of Occupational Risk Prevention (Law 31/1995) and the Fire Safety Regulations for Industrial Establishments (RSCIEI).

Here digital forms become a strategic ally. Companies can use digital process checklists to control temperatures, pressures and consumption, record shrinkage or incidents, and generate automatic efficiency reports. They can also implement waste control forms to ensure the correct classification and destination according to the LER code (European Waste List).

In addition, through integration with sensors or production control systems (SCADA), the forms allow automated collection of emissions or energy consumption data, helping to comply with the reduction and efficiency obligations established by Law 7/2022.

Benefits of online forms

The main benefit of implementing FIELDEAS Forms digital forms in the plastics industry and applying them in the transformation phase is to achieve comprehensive control of waste, energy efficiency and industrial safety, all backed by a validated digital record that guarantees traceability and verification of each piece of data.

Digital forms in the manufacturing stage of food contact packaging or materials

When plastic products are intended for food packaging, very specific regulations come into play: Regulation (EU) 10/2011; Regulation (EC) 1935/2004; and Regulation (EC) 2023/2006 on Good Manufacturing Practices (GMP).

Therefore, digital forms are essential to maintain the traceability and quality control required by these regulations, as they allow the digital documentation of GMP inspections, cleanings, migration tests and batch traceability.

In addition, certificates of analysis and photographic evidence can be attached directly to each record.

With digital forms software, audits are simplified: all information is centralized and accessible, drastically reducing verification time and increasing data reliability.

Benefits of digital forms

The primary benefit of using FIELDEAS Forms intelligent online forms software in food packaging manufacturing is automated Good Manufacturing Practice (GMP) compliance and full product traceability.

Intelligent forms in the environmental and waste management phase

In this phase, plastic waste, wastewater, emissions and discharges are managed. The main regulations are Law 7/2022; RD 553/2020 on waste shipments; the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal; and the Public Hydraulic Domain Regulations (RD 849/1986).

With this in mind, the digital forms allow the creation of electronic waste records (type, quantity, authorized manager, destination), continuously controlling the generation and internal management.

They can also incorporate discharge control forms with automatic parameters (pH, Chemical Oxygen Demand, temperature) and issue alerts if established limits are exceeded.

In addition, these systems can generate automatic environmental compliance reports for the competent authorities, guaranteeing document traceability without relying on paper records.

Benefits of smart forms

The main benefit of implementing FIELDEAS Forms in the plastics industry in environmental management is to achieve total control of waste and spills, ensuring compliance with Law 7/2022 on waste and contaminated soils, and significantly reducing the risk of environmental sanctions.

Digital forms in the marketing phase and taxation of plastics

With the entry into force of Law 7/2022, producers must comply with new tax and extended responsibility obligations: excise tax on non-reusable plastic packaging (€0.45/kg); Product Producers Register; compliance with Directive (EU) 2019/904 on single-use plastics.

Here, digital forms in the plastics industry make it possible to record the weight of virgin and recycled plastic used in each product, automate the tax calculation and generate official reports for the Tax Agency (AEAT).

They also help manage the traceability of packaging placed on the market and ensure compliance with EPR (Extended Producer Responsibility) obligations.

Benefits of digital forms

The main benefit of using FIELDEAS Forms digital forms in the marketing and taxation stage of the plastic is to achieve automated tax control, which reduces errors and ensures transparent compliance with the administration.

Online forms in industrial and occupational safety and security

Safety is transversal to the whole process. Standards such as Law 31/1995 on Occupational Risk Prevention; RD 1215/1997, which establishes the minimum health and safety provisions for the use of work equipment by workers; RD 374/2001, on the protection of the health and safety of workers against risks related to chemical agents at work; the RSCIEI; and the APQ set the guidelines.

The digital forms allow daily safety inspections, verify the use of personal protective equipment (PPE), record maintenance and drills, and even report incidents with photos and geolocation.

In addition, a good digital forms solution can generate automatic alerts for pending revisions or certifications.

Main benefit of online forms in security

The main benefit of implementing FIELDEAS Forms’ intelligent digital forms solution in the plastics industry in terms of occupational safety is that it improves the preventive culture, guarantees the traceability of all safety actions and facilitates the performance of labor audits or industrial inspections.

Digital forms software in the plastics industry

Digital forms in the plastics industry are not only a digitization tool, but a key piece to keep under control all phases of the production process, from the receipt of raw materials to the final marketing, ensuring traceability, safety, operational efficiency and regulatory compliance in a highly regulated sector.

In this context, FIELDEAS Forms is positioned as the most complete digital forms software on the market, thanks to its flexibility, customization capacity and scalability, which allow it to be adapted to the specific needs of each manufacturer.

Thus, implementing a solution such as FIELDEAS Forms means taking a decisive step towards a more responsible, sustainable and transparent production, aligned with the principles of the circular economy and the regulatory requirements of Spain and the European Union, also facilitating the automation of records, audits and reports with full legal validity and digital traceability.